How to select the right control valve

The following conditions should be taken into consideration in order to select the right solution for your application:

• Working conditions

• Maximum flow

• Minimum flow

• Continuous flow

• Maximum inlet pressure

• Minimum inlet pressure

• Wanted outlet pressure

• Pipe size

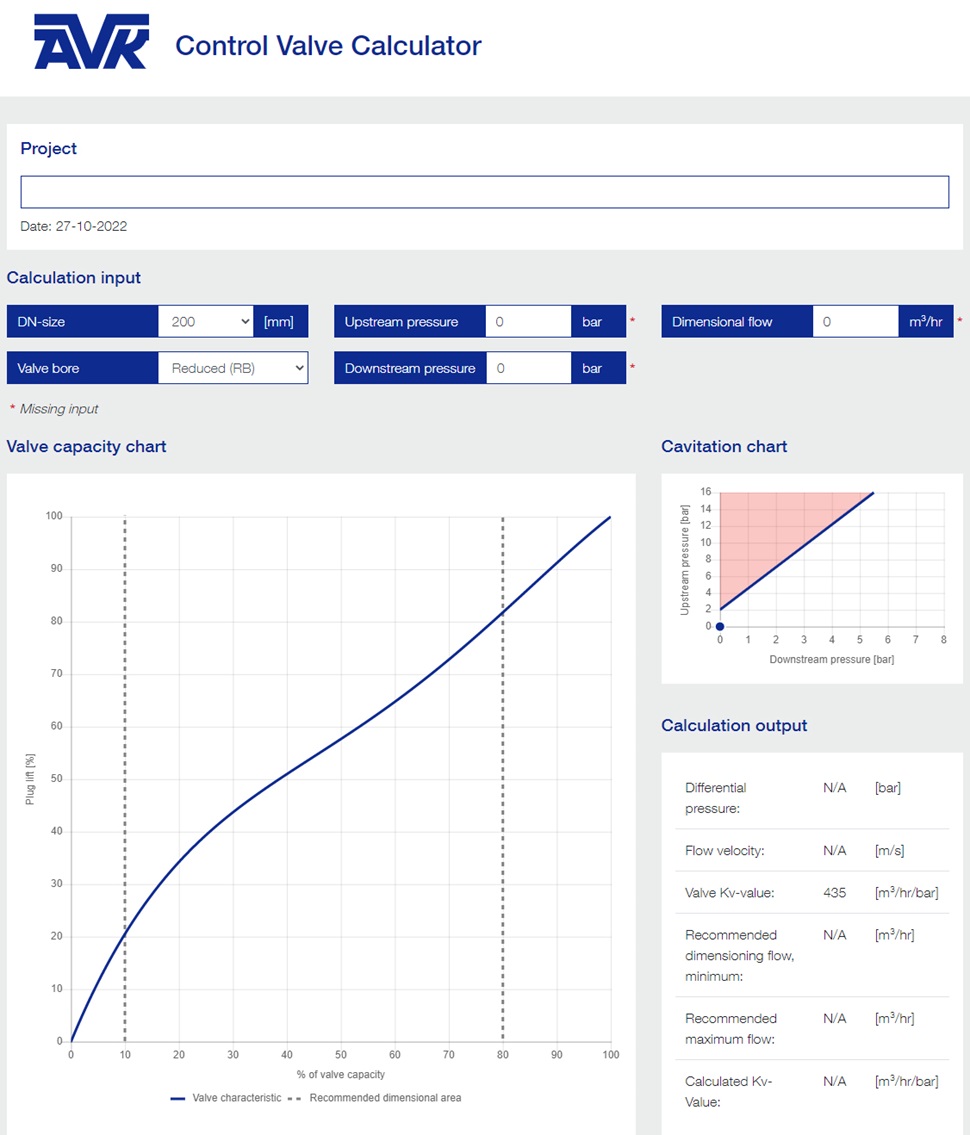

Our online sizing tool provides guidelines for the selection.

Control valve variants and configurations

Pressure reducing, pressure sustaining/relief valves and constant flow valves are part of our standard range, and with our online sizing tool you will get guidance for selection of the suitable type and dimension. On request, we also offer control valve variants such as:

• Surge anticipation valve

Automatically protects the pipe system against pressure surges, mainly happening at pump start-up, or in the event of failure.

• Altitude valve

Automatically controls the water levels in tanks or reservoirs.

One-way: The altitude pilot senses the water level and opens to refill, once the level drops below set point.

Two-way: Like one-way, but furthermore, the valve opens for returning the flow in case the inlet pressure is lower than the tank/reservoir pressure.

• Float level valve

Automatically controls the water levels in tanks or reservoirs.

Modulating: The modulating float is remotely installed and controls the tank/reservoir level at a defined set point. The valve closes tightly at desired level and opens, if filling is needed.

Non-modulating: The non-modulating float keeps the valve closed until the tank/reservoir level reaches the minimum acceptable set point. Then the control valve opens fully to refill, until it reaches the maximum acceptable set point, and the valve closes.

• Solenoid control valve

Automatically either closes or opens the main valve.控制主阀自动开启或关闭

• Dual solenoid control valve

Automatically controlled by electrical signals. The control valve offers full regulation of pressure, flow and level.

由电信号进行自动控制,使得控制阀可以提供全面的压力、流量及液位调节功能

• Optional configurations

AVK also offers accessories such as pressure gauges and position indicators as well as special configurations e.g. with PLC, electrical actuator, built-in anti-cavitation trim, lifting lugs and flush valve on the filter.

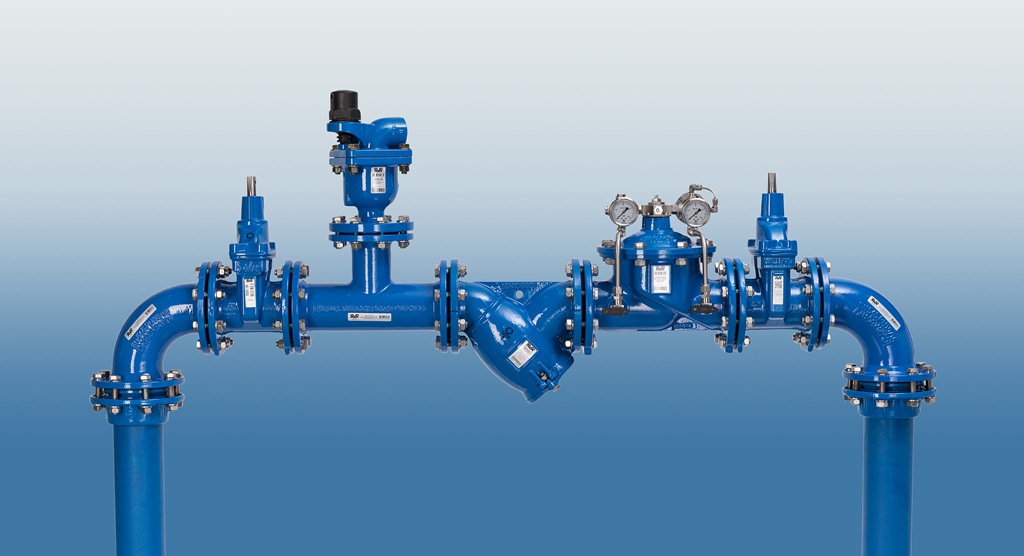

The importance of strainers and isolating valves

It is highly recommended to install a protection strainer on the inlet side of the control valve, to filter out impurities that could damage the control valve, or cause loss of control. Isolating valves on each side of the control valve facilitate commissioning and maintenance. Installation of by-pass for keeping up the supply, in case of main valve maintenance on the control valve is recommended.

Use of air valves

In many cases it is recommendable to install an air valve at the inlet of the control valve in order to avoid trapped air pockets in the system, and air in the system in general will cause the valve to regulate with less accuracy. Air pockets may cause increased energy consumption and operation costs, pressure loss and increased risk of water hammer.